This manual provides a comprehensive guide to understanding and troubleshooting ignition coil wiring systems․ It covers various types of ignition coils, common wiring configurations, and essential safety precautions․ The information presented here is intended for automotive enthusiasts, mechanics, and anyone interested in learning more about ignition coil wiring․

Introduction

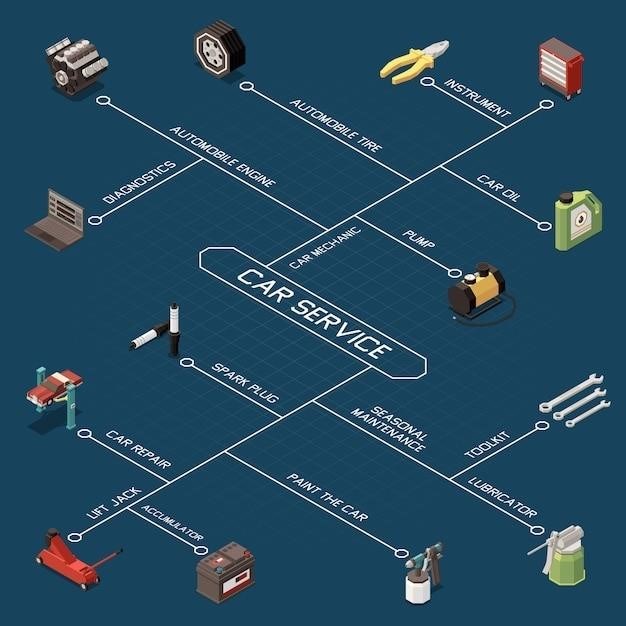

The ignition coil is a crucial component in any gasoline-powered vehicle’s ignition system․ It plays a vital role in converting the low voltage supplied by the battery into a high-voltage spark that ignites the air-fuel mixture in the combustion chamber․ Understanding the wiring of an ignition coil is essential for troubleshooting and maintenance․ This manual aims to provide a comprehensive overview of ignition coil wiring diagrams, explaining the different types of coils, common configurations, and troubleshooting techniques․

This guide will delve into the intricacies of ignition coil wiring, covering both the primary and secondary circuits․ We will examine the various components involved, including the ignition module, the distributor, and the spark plug wires․ By understanding the principles behind ignition coil wiring, you will be better equipped to diagnose issues, perform repairs, and ensure the optimal performance of your vehicle’s ignition system․

Types of Ignition Coils

Ignition coils come in various designs, each tailored to specific applications and vehicle types․ The most common classifications are based on the number of coils within the unit and the location of the coil in the ignition system․

Single-coil systems utilize a single ignition coil to deliver spark to multiple cylinders, typically through a distributor․ This configuration is common in older vehicles with a traditional ignition system․ Multi-coil systems, on the other hand, employ a separate coil for each cylinder, often referred to as “coil-on-plug” (COP) systems․ This setup eliminates the need for a distributor, simplifying wiring and improving ignition performance․

Coil-on-plug systems are becoming increasingly prevalent in modern vehicles due to their efficiency and reliability․ They provide a direct path for spark delivery, eliminating the potential for spark leakage and ensuring precise timing for each cylinder․ Understanding the specific type of ignition coil in your vehicle is crucial for interpreting wiring diagrams and troubleshooting any issues․

Wiring Diagram Basics

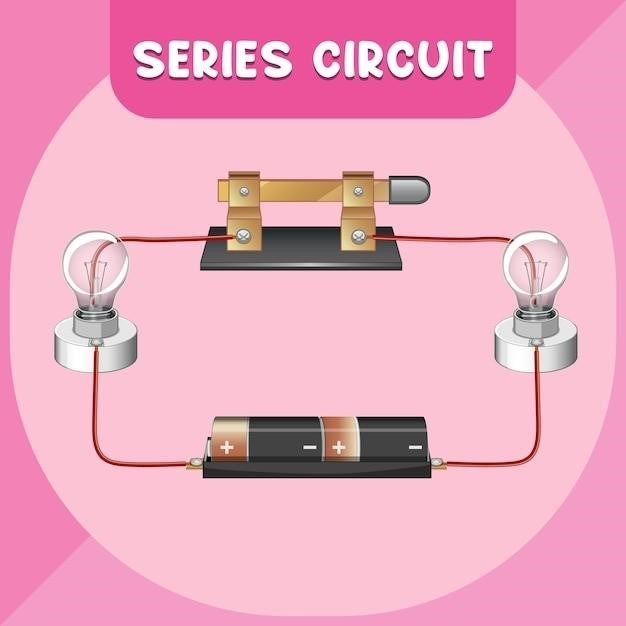

Ignition coil wiring diagrams are visual representations of the electrical connections within the ignition system․ They serve as essential tools for understanding how components are interconnected and for troubleshooting potential problems․ These diagrams typically use standardized symbols to represent various components, such as the ignition coil, spark plugs, ignition control module (ICM), and battery․ Lines connecting these symbols indicate the flow of electrical current․

The primary purpose of an ignition coil wiring diagram is to provide a clear and concise visual guide for understanding the electrical path from the battery to the spark plugs․ By following the lines and symbols, you can trace the flow of electricity and identify any potential points of failure․

For example, a wiring diagram will show how the battery supplies power to the ignition coil, how the ICM controls the timing of the spark, and how the spark plugs receive the high-voltage current necessary to ignite the fuel․ These diagrams are essential for professionals and DIY enthusiasts alike, enabling them to diagnose problems and make necessary repairs․

Common Ignition Coil Configurations

Ignition coil configurations vary depending on the vehicle and engine type․ The two most common configurations are single-coil and multi-coil systems․ Each system has its own unique wiring arrangement and characteristics․

Single-coil systems, also known as wasted spark systems, use a single ignition coil to provide spark to two cylinders simultaneously․ This configuration is typically found in older vehicles with four-cylinder engines․ The single coil’s output is distributed to the spark plugs via a distributor cap and rotor․

Multi-coil systems, often found in modern vehicles, utilize multiple ignition coils, typically one per cylinder․ This configuration eliminates the need for a distributor and provides a more precise and efficient spark delivery to each cylinder․ Each coil is directly connected to its corresponding spark plug, simplifying wiring and improving performance․

Understanding the specific configuration of your vehicle’s ignition system is crucial for diagnosing and repairing any wiring issues․ By consulting the correct wiring diagram and recognizing the type of coil system used, you can accurately troubleshoot problems and ensure proper functionality․

Single Coil Systems

Single-coil systems, also known as wasted spark systems, utilize a single ignition coil to provide spark to two cylinders simultaneously․ This configuration is typically found in older vehicles with four-cylinder engines․ The single coil’s output is distributed to the spark plugs via a distributor cap and rotor․

The distributor cap acts as a switch, directing the high-voltage spark from the coil to the appropriate spark plug based on the engine’s firing order․ The rotor, a rotating component inside the distributor cap, makes contact with the distributor cap terminals, transferring the spark to the corresponding spark plug wire․

In a single-coil system, when the coil fires, it produces a spark to both cylinders simultaneously․ This is referred to as “wasted spark” because only one cylinder is actually firing at a time, while the other cylinder is on its exhaust stroke․ Despite this, the wasted spark still contributes to a more efficient combustion process, as it helps to ignite the remaining exhaust gases, reducing emissions․

Single-coil systems are relatively simple in design and offer a cost-effective solution for older vehicles․ However, they can be prone to issues with distributor cap wear, rotor failure, and spark plug wire deterioration, which can affect performance and reliability․

Multi-Coil Systems

Multi-coil systems, also known as coil-on-plug (COP) systems, have become increasingly common in modern vehicles․ This configuration eliminates the need for a distributor, as each cylinder has its own dedicated ignition coil mounted directly on top of the spark plug․ The individual coils receive signals from the engine control module (ECM) to fire independently, providing a more precise and efficient spark for each cylinder․

The ECM controls the timing and duration of the spark for each coil, ensuring optimal ignition and combustion․ This system offers several advantages over single-coil systems, including improved performance, reduced emissions, and enhanced reliability․ The direct connection between the coil and spark plug eliminates the potential for spark plug wire issues and reduces the risk of cross-firing between cylinders․

Multi-coil systems also allow for more precise control over the ignition timing, as the ECM can adjust the firing order and timing for each cylinder independently․ This results in a smoother engine operation and better fuel economy․ Additionally, the absence of a distributor cap and rotor eliminates wear and tear on these components, further enhancing the system’s longevity․

While multi-coil systems are generally more advanced and reliable, they can be more complex to diagnose and repair compared to single-coil systems․ However, the benefits they offer in terms of performance, efficiency, and reliability have made them the preferred choice for modern vehicles․

Understanding Ignition Coil Wiring

The wiring diagram for an ignition coil is essential for understanding how it operates and troubleshooting any potential issues․ It shows the flow of electricity through the coil, connecting the battery, ignition switch, ignition module, and spark plugs․ The diagram typically uses symbols and colors to represent different components and wires, making it easier to follow the path of the electrical current․

The ignition coil’s primary circuit receives power from the battery and ignition switch․ This current flows through the primary winding of the coil, creating a magnetic field․ When the ignition module or ECM interrupts the primary circuit, the magnetic field collapses rapidly, inducing a high-voltage pulse in the secondary winding․ This high voltage is then sent to the spark plugs, igniting the air-fuel mixture in the combustion chamber․

The secondary circuit is the high-voltage side of the ignition coil, directly connected to the spark plug․ The high-voltage pulse generated by the collapsing magnetic field travels through the secondary winding and then to the spark plug via the spark plug wire․ The spark plug wire is a high-voltage cable that carries the electrical current from the coil to the spark plug, ensuring a reliable and consistent spark․

Understanding the primary and secondary circuits of an ignition coil is crucial for effective troubleshooting․ It helps to identify the cause of problems like misfiring, lack of spark, or engine starting issues․ By tracing the flow of electricity through the circuits, you can pinpoint the faulty component and replace it accordingly․

Primary Circuit

The primary circuit of an ignition coil is the low-voltage side of the system, responsible for creating the magnetic field that drives the high-voltage output․ It’s a relatively simple circuit, consisting of the battery, ignition switch, ignition module (or ECM), and the primary winding of the coil․ The primary circuit can be viewed as a control circuit, regulating the flow of electricity to the coil․

When the ignition switch is turned on, battery power flows through the primary circuit․ The ignition module or ECM then controls the flow of current to the primary winding, turning it on and off rapidly․ This interruption of current causes a rapid collapse of the magnetic field in the primary winding, inducing a high-voltage pulse in the secondary winding․ This pulse is then sent to the spark plug to ignite the air-fuel mixture․

The primary circuit is essential for creating the spark needed for combustion․ Any issues with the primary circuit, such as a faulty ignition switch, a broken wire, or a malfunctioning ignition module, can disrupt the flow of current and prevent the coil from generating a spark․ Therefore, it’s crucial to diagnose and repair any problems in the primary circuit to ensure the proper functioning of the ignition system․

Secondary Circuit

The secondary circuit of an ignition coil is the high-voltage side, responsible for generating the powerful spark that ignites the air-fuel mixture in the combustion chamber․ This circuit consists of the secondary winding of the coil, the spark plug wire, and the spark plug itself․ The secondary winding is wrapped around the primary winding, but with many more turns of wire․ This creates a much higher inductance, which is crucial for boosting the voltage․

When the primary circuit is interrupted, the collapsing magnetic field in the primary winding induces a high-voltage pulse in the secondary winding․ This pulse travels through the spark plug wire, a high-voltage cable designed to resist electrical breakdown, and reaches the spark plug․ The spark plug’s electrode gap is designed to create a spark when the high voltage reaches a certain threshold․

The secondary circuit is crucial for efficient combustion and engine performance․ If there is a problem in the secondary circuit, such as a broken spark plug wire, a faulty spark plug, or a damaged secondary winding, the spark may be weak or absent, resulting in misfires, poor fuel economy, and reduced engine power․

Troubleshooting Ignition Coil Wiring

Troubleshooting ignition coil wiring involves a systematic approach to identify and resolve issues that may be preventing the ignition system from functioning properly․ It’s essential to have a basic understanding of the ignition coil wiring diagram and the principles of operation․ This will help you pinpoint the source of the problem and implement the appropriate solution․

The first step is to visually inspect the wiring for any obvious signs of damage, such as frayed wires, loose connections, or corrosion․ You should also check the spark plug wires for cracks or breaks in the insulation․ If any damage is found, it needs to be repaired or replaced․

If a visual inspection doesn’t reveal any problems, you can use a multimeter to test the continuity of the wires and the resistance of the ignition coil․ This will help you determine if there are any breaks or short circuits in the wiring․ If you find any issues, you may need to replace the damaged wires or repair the connection․

Identifying Common Problems

Identifying common problems with ignition coil wiring is crucial for effective troubleshooting․ These issues can stem from various factors, including age, wear and tear, environmental exposure, and improper installation․ Understanding the potential culprits allows you to target your diagnostics more efficiently․

One frequent problem is corroded connections․ This occurs when moisture or other contaminants accumulate on the terminals, hindering electrical conductivity․ Another common issue is loose or broken wires․ These can result from vibrations, physical damage, or improper handling during repairs․ A third concern is damaged ignition coils themselves․ These may exhibit internal faults, such as broken windings or shorted circuits, leading to reduced spark output or complete failure․

Finally, faulty ignition control modules (ICMs) can also contribute to ignition coil wiring problems․ These modules regulate the timing and duration of the spark, and if malfunctioning, can cause irregular or weak spark delivery․ Identifying these common issues allows you to focus your troubleshooting efforts on the most likely causes, ultimately leading to a quicker and more effective resolution․

Testing the Ignition Coil

Testing an ignition coil involves verifying its ability to generate the high voltage necessary to spark the fuel-air mixture in the engine’s combustion chamber․ This process typically involves checking both the primary and secondary circuits of the coil․ The primary circuit deals with the low voltage current flow from the battery, while the secondary circuit handles the high voltage output to the spark plugs․

A common method for testing the primary circuit is measuring its resistance using a multimeter․ This helps determine if the coil’s windings are intact and not shorted․ Testing the secondary circuit requires a specialized tool called a spark tester․ This device simulates the spark plug and allows you to visually observe the spark generated by the coil, verifying its strength and consistency․

While testing, it’s essential to follow safety precautions, as high voltage can be dangerous․ Always disconnect the battery before working on the ignition system, and avoid touching any exposed terminals or wires․ By performing these tests, you can diagnose potential problems with the ignition coil and determine if it needs replacement or further investigation․

Safety Precautions

Working with an ignition system, particularly the ignition coil, involves high voltage and can be dangerous if proper precautions are not taken․ Before attempting any work on the ignition coil, it’s crucial to disconnect the battery terminals to prevent electrical shock․ This ensures that no power is flowing through the system while you’re working on it․

Always wear appropriate safety gear, such as insulated gloves and safety glasses, to protect yourself from potential electrical hazards․ Be cautious while handling the ignition coil and avoid touching exposed terminals or wires, especially when the system is energized․ Additionally, keep flammable materials away from the work area, as sparks from the ignition system could ignite them․

If you are unsure about any aspect of the wiring or testing procedure, consult a qualified mechanic or refer to the vehicle’s service manual for specific instructions․ By following these safety precautions, you can minimize the risk of injury and ensure a safe working environment when dealing with ignition coil wiring․