Briggs & Stratton engines power a vast array of outdoor equipment; comprehensive service manuals are essential for owners and technicians alike, ensuring optimal performance and longevity.

These manuals provide detailed instructions, diagrams, and specifications crucial for maintaining and repairing these ubiquitous powerhouses, extending their operational lifespan.

Importance of a Service Manual

A Briggs & Stratton service manual is far more than just a collection of pages; it’s a critical resource for anyone owning or servicing their engines. These manuals unlock the secrets to proper maintenance, preventing costly repairs down the line and maximizing engine life. They empower users to diagnose issues accurately, avoiding unnecessary component replacements.

Detailed exploded views and parts lists simplify repairs, while torque specifications ensure correct assembly. Ignoring a manual can lead to improper repairs, voiding warranties and potentially causing further damage. Furthermore, safety precautions within the manual are paramount, protecting both the user and the equipment. Investing in, and utilizing, a service manual is an investment in the longevity and reliable operation of your Briggs & Stratton engine.

Types of Briggs & Stratton Engines Covered

Briggs & Stratton manufactures a remarkably diverse range of engines, and correspondingly, a wide variety of service manuals exist. These cover everything from small, single-cylinder engines found in lawnmowers and portable generators, to larger, more complex V-Twin engines powering garden tractors and commercial equipment.

Manuals are categorized by engine series (e.g., Intek, Vanguard), displacement (e.g., 5HP, 19HP), and model number. Specific manuals address horizontal shaft and vertical shaft configurations, as well as those with electric start or recoil start systems. The PowerPortal website caters to dealers, offering specialized training and resources. Therefore, identifying the precise engine type is crucial for selecting the correct, applicable service documentation.

Locating the Correct Service Manual

Finding the right manual requires your engine’s specific model number; this ensures compatibility and accurate repair information for your Briggs & Stratton engine.

Using the Engine Model Number

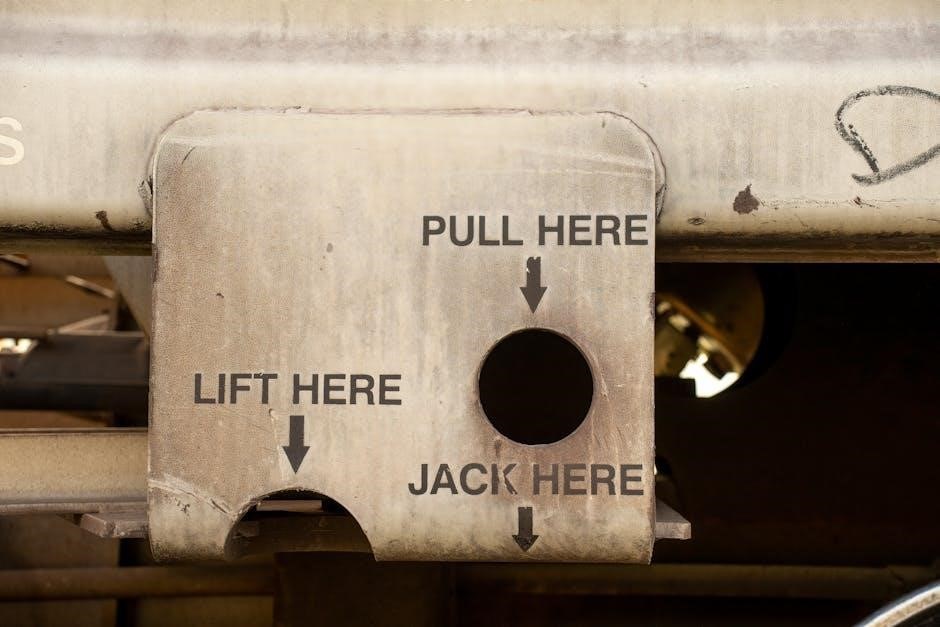

The engine model number is the key to unlocking the correct Briggs & Stratton service manual. This unique identifier, typically found on the engine’s valve cover or blower housing, precisely identifies your engine’s specifications and components.

Locate this number – it’s a combination of letters and numbers – and carefully record it. When searching online or contacting Briggs & Stratton directly, inputting this number guarantees you receive the manual tailored to your specific engine.

Incorrect manuals can lead to improper repairs, potentially damaging your engine or creating safety hazards. Double-check the number for accuracy before proceeding with your search. Utilizing the model number streamlines the process, saving you time and frustration, and ensuring a successful repair experience.

Briggs & Stratton Website Resources

The official Briggs & Stratton website (briggsandstratton.com) is a primary resource for locating service manuals. Their “Support” section offers a dedicated area for manual downloads, searchable by engine model number. This ensures you access the most accurate and up-to-date documentation for your specific engine.

Beyond downloadable PDFs, the website often features interactive parts diagrams and troubleshooting guides. These resources can assist with identifying components and diagnosing common issues. Registering your engine on the site provides access to personalized support and warranty information.

Regularly check the website for updates and revisions to existing manuals, guaranteeing you’re working with the latest information available.

Third-Party Manual Providers

While the Briggs & Stratton website is the preferred source, several third-party providers offer service manuals, both in digital and physical formats. These include online retailers specializing in technical documentation and auction sites featuring used manuals.

However, exercise caution when using these sources. Verify the manual’s accuracy and completeness, ensuring it corresponds to your engine’s specific model and year. Beware of potentially fraudulent or outdated manuals lacking essential information.

Reputable providers often offer previews or detailed descriptions. Always compare pricing and read reviews before purchasing to ensure a legitimate and valuable resource.

Understanding the Manual’s Structure

Briggs & Stratton manuals are logically organized, beginning with safety guidelines, followed by detailed parts lists, and concluding with specific repair procedures for ease of use.

Safety Precautions and Warnings

Prioritizing safety is paramount when working with Briggs & Stratton engines. Always disconnect the spark plug wire before performing any maintenance to prevent accidental starting; Fuel is highly flammable; store it in approved containers away from heat sources and open flames.

Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Never operate an engine in an enclosed space due to the risk of carbon monoxide poisoning. Be mindful of hot surfaces, such as the muffler and engine block, to avoid burns.

Properly dispose of used oil and other fluids according to local regulations. Understand the potential hazards associated with each repair procedure and consult the manual for specific warnings. Ignoring these precautions can lead to serious injury or damage.

Parts Diagrams and Identification

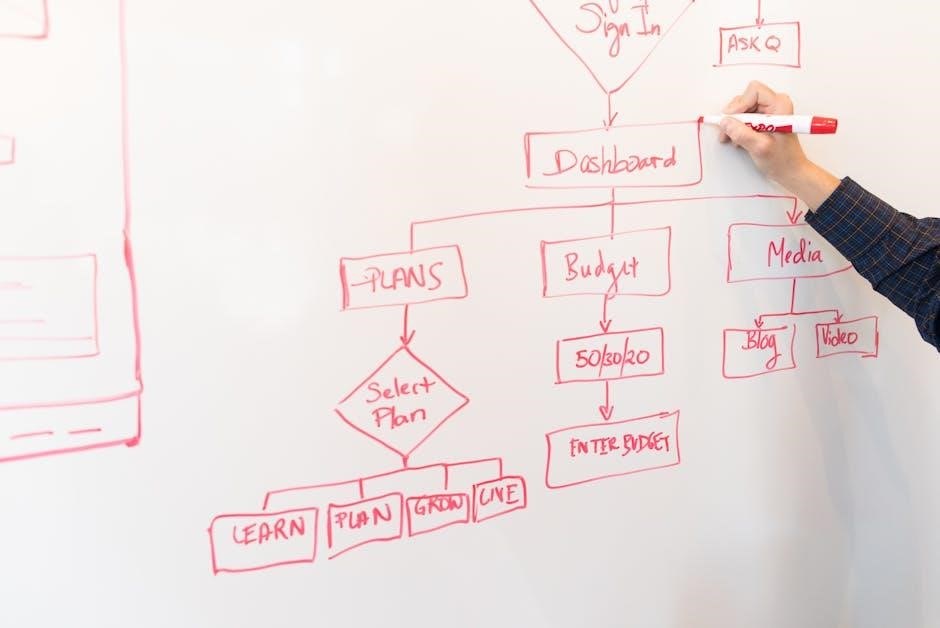

Briggs & Stratton service manuals feature detailed exploded-view diagrams illustrating the precise arrangement of engine components. These diagrams are invaluable for identifying parts during disassembly, repair, or replacement. Each part is typically labeled with a unique reference number, cross-referenced to a comprehensive parts list.

The parts list provides detailed descriptions, part numbers, and often, compatibility information for various engine models; Accurate part identification is crucial to ensure proper fit and function. Utilizing these diagrams minimizes errors and streamlines the repair process.

Understanding how to interpret these visual guides significantly reduces downtime and ensures the correct components are ordered, saving both time and money.

Torque Specifications

Briggs & Stratton service manuals meticulously detail torque specifications for every fastener on the engine. Applying the correct torque is paramount; under-tightening can lead to loosening and failure, while over-tightening risks stripping threads or damaging components.

These specifications are typically presented in tables, categorized by fastener size, thread type, and location on the engine. Units are commonly expressed in foot-pounds (ft-lbs) or Newton-meters (Nm).

Adhering to these values ensures proper clamping force, preventing leaks, vibrations, and premature wear. Using a calibrated torque wrench is highly recommended for accurate results, maximizing engine reliability and longevity.

Common Engine Problems & Troubleshooting

Briggs & Stratton manuals offer systematic troubleshooting guides for frequent issues like starting failures, low oil shutdowns, and carburetor malfunctions, aiding swift diagnosis.

Engine Won’t Start

If your Briggs & Stratton engine fails to start, the service manual directs you to check several key components. First, verify the fuel system: is there adequate fuel in the tank, and is the fuel shut-off valve open? Next, inspect the spark plug – is it clean, properly gapped, and receiving a spark? A faulty spark plug is a common culprit.

The manual also emphasizes checking the air filter for obstructions, as a clogged filter restricts airflow. Confirm the choke is functioning correctly, especially in cold weather. Low compression can also prevent starting; the manual details compression testing procedures. Finally, ensure the safety interlocks, like the low oil sensor, aren’t preventing operation. Following these steps, guided by the manual’s diagrams, will pinpoint the issue.

Low Oil Shutdown Issues

Briggs & Stratton engines feature a low oil shutdown system, protecting against damage from insufficient lubrication. If the engine stops running shortly after starting, the service manual instructs you to first check the oil level; Ensure it’s within the recommended range, and that the correct oil type is used. A faulty low oil sensor is another common cause; the manual provides testing procedures using a multimeter.

Inspect the sensor wiring for damage or loose connections. Sometimes, a clogged oil passage can falsely trigger the sensor. The manual details how to access and clean these passages. Remember, bypassing the low oil shutdown is strongly discouraged, as it risks severe engine damage. Always address the root cause, guided by the manual’s troubleshooting steps.

Carburetor Problems

Carburetor issues are frequent with Briggs & Stratton engines, often manifesting as hard starting, rough idling, or lack of power. The service manual emphasizes the importance of a clean carburetor for optimal fuel delivery. It provides detailed instructions for disassembly, cleaning, and reassembly, highlighting specific jets and passages prone to clogging.

Inspect the float, needle valve, and seat for wear or damage. The manual includes diagrams illustrating proper component placement. Fuel stabilizer is recommended for storage to prevent varnish buildup. If problems persist, the manual guides you through adjusting the carburetor settings, ensuring the correct air-fuel mixture for smooth operation. Always consult the manual before attempting carburetor repairs.

Maintenance Procedures

Regular maintenance, as detailed in the service manual, is vital for Briggs & Stratton engine reliability and longevity, preventing costly repairs down the line.

Oil Change Procedures

Consistent oil changes are paramount for Briggs & Stratton engine health, extending its lifespan and ensuring optimal performance. The service manual outlines a step-by-step process, beginning with warming the engine for easier oil flow. Locate the oil drain plug, typically at the engine’s base, and position a suitable oil drain pan underneath.

Carefully remove the plug, allowing the old oil to drain completely. Replace the drain plug and tighten it securely, referencing torque specifications in the manual. Next, remove the oil fill cap and add the recommended oil type and quantity, checking the oil level with the dipstick. Avoid overfilling. Properly dispose of the used oil at a designated recycling center, adhering to local environmental regulations.

Spark Plug Replacement

Regular spark plug replacement is vital for maintaining efficient engine combustion in Briggs & Stratton engines. The service manual details the procedure, starting with disconnecting the spark plug wire to prevent accidental starting. Utilize a spark plug socket to carefully remove the old spark plug, noting its condition for diagnostic clues.

Gap the new spark plug to the manufacturer’s specified setting, using a spark plug gapping tool. Thread the new spark plug into the cylinder head by hand to avoid cross-threading, then tighten it to the correct torque specification outlined in the manual. Reconnect the spark plug wire securely. A properly functioning spark plug ensures reliable engine starts and smooth operation.

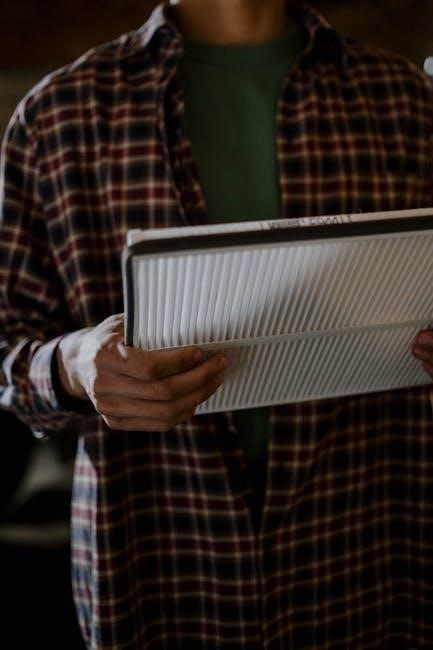

Air Filter Cleaning/Replacement

Maintaining a clean air filter is crucial for optimal Briggs & Stratton engine performance, preventing debris from entering the carburetor. The service manual guides users through both cleaning and replacement procedures. For foam filters, wash gently with soap and water, ensuring it’s fully dry before re-oiling lightly.

Paper filters should be tapped gently to remove loose dirt; replacement is recommended when visibly soiled. Locate the air filter housing, remove the cover, and install the clean or new filter correctly. A restricted air filter reduces engine power and fuel efficiency, so regular checks are essential for longevity.

Advanced Repair Procedures

Complex repairs, like valve adjustments, governor fixes, and recoil starter overhauls, demand specialized knowledge; the service manual provides detailed steps and diagrams for skilled technicians.

Valve Adjustment

Proper valve clearance is critical for optimal engine performance, impacting compression, fuel efficiency, and overall longevity. The Briggs & Stratton service manual details a precise procedure for adjusting valve lash, typically involving removing the valve cover and utilizing a feeler gauge.

The manual specifies the correct clearance specifications for each engine model, ensuring accurate settings. Rotating the engine to specific crankshaft positions allows for individual valve adjustments. Incorrect valve adjustment can lead to engine misfires, reduced power, and potential valve damage.

Following the manual’s step-by-step instructions, including torque specifications for the valve cover bolts, is paramount for a successful and reliable repair. Regular valve adjustments, as outlined in the maintenance schedule, are preventative measures.

Governor Repair

The governor maintains consistent engine speed under varying loads; a malfunctioning governor results in surging, unstable RPMs, or inability to reach rated speed. Briggs & Stratton service manuals provide detailed disassembly, inspection, and repair procedures for governor components.

Common issues include a sticking governor arm, worn governor springs, or a faulty governor gear. The manual illustrates proper lubrication points and specifies torque values for reassembly. Careful attention to detail is crucial during reinstallation, ensuring correct linkage and spring tension.

Testing the governor’s operation after repair, as described in the manual, verifies proper functionality and prevents further engine issues. Ignoring governor problems can lead to engine damage.

Recoil Starter Repair

The recoil starter allows for manual engine starting; a faulty recoil starter prevents easy engine ignition, often due to a broken pawl, worn spring, or damaged rope. Briggs & Stratton service manuals offer step-by-step instructions for disassembly, inspection, and replacement of recoil starter components.

The manual details proper spring tensioning and pawl engagement, crucial for reliable starting. Illustrations clearly show the correct orientation of parts during reassembly. Lubrication of moving parts, as specified, ensures smooth operation.

Replacing a worn recoil rope or a damaged starter housing restores easy starting functionality, preventing frustration and potential engine damage from excessive pulling.

Reporting Fraudulent Activity Related to Manuals/Parts

Protect yourself from scams involving fake manuals or parts; report suspicious websites and activity directly to Briggs & Stratton to safeguard your financial information.

Identifying Scam Manuals or Websites

Be vigilant when sourcing Briggs & Stratton service manuals online. Scam manuals often feature poor print quality, missing pages, or inaccurate information compared to official publications. Websites selling these fraudulent resources may have unprofessional designs, lack secure payment options, or request excessive personal details.

Look for discrepancies in pricing – significantly lower prices than authorized dealers should raise red flags. Beware of sites promising “free” downloads that require completing numerous surveys or downloading suspicious software. Always verify the website’s legitimacy by checking for a valid SSL certificate (https:// in the address bar) and a clear contact information section. Scammers frequently impersonate legitimate companies, so carefully examine the website’s domain name for subtle misspellings or variations.

Reporting Suspicious Activity to Briggs & Stratton

If you encounter a suspected fraudulent manual or website claiming to be affiliated with Briggs & Stratton, report it immediately. Gather as much information as possible, including the website URL, screenshots of the suspicious content, and any communication you’ve had with the seller.

Contact Briggs & Stratton’s customer support through their official website (briggsandstratton.com) and provide them with the collected details. They have dedicated channels for investigating and addressing such issues. Reporting helps protect other customers and allows Briggs & Stratton to take appropriate action against counterfeiters. Document your report for your records, including the date and time of submission, and any reference number provided.

Protecting Your Financial Information

When purchasing Briggs & Stratton service manuals or parts online, prioritize secure payment methods. Avoid using direct bank transfers or sending money via unsecured platforms. Opt for credit cards or reputable payment processors like PayPal, which offer fraud protection and dispute resolution services.

Always verify the website’s security by checking for “https” in the URL and a padlock icon in the address bar. Be wary of unsolicited emails or offers requesting your financial details. Never share your credit card information or bank account numbers with unverified sources. Regularly monitor your bank and credit card statements for any unauthorized transactions.